Enhanced TDS

Identification & Functionality

- Supplied By

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

Applications & Uses

- Markets

- Applications

- Segments

- Applications

- Applicable Processes

- Industrial Additives End Use

- Application Information

- As an acid viscosifier, for reducing fluid loss, extending acid spending time and improving stimulation results by increasing live acid penetration

- As a thickener for Slick Water Fracturing

- As a thickener for fresh water or brines in workover and completion operations

- In conformance control applications, HE®300 Polymer provides superior high temperature stability. It is generally reserved for application where reservoir temperatures exceed 240 °F. It can be readily cross-linked with various organic systems, including phenol formaldehyde, resorcinol-formaldehyde, phenyl acetateHMTA or hydroquinone-HMTA. Polymer loadings as high as 14 lb/BBL may be used in order to maximize gel rigidity in water shutoff treatments.

- As a high temperature fluid loss additive in silicate drilling fluids

- Advantages Information

- Hydrates rapidly in most aqueous systems

- Resists thermally induced hydrolysis

- Maintains solubility at high temperatures

- Thickens brines of various compositions

- Improves carrying capacity of fluids

- Gel able with various organic cross-linkers

- High tolerance to changes in pH

Properties

- Physical Form

- Soluble In

- Notes

HE® 300 Polymer is an inherently clean thickener, posing very little risk of formation damage under normal usage conditions. The HE® 300 Polymer is readily soluble in normal wellbore cleanup type acids. The polymer is degradable using oxidizing agents, such as sodium hypochlorite (bleach) or ammonium persulfate. The activity of the oxidizer is generally enhanced by using fluid with a basic pH. Degradation by oxidizers is also enhanced at temperatures above 125 °F.

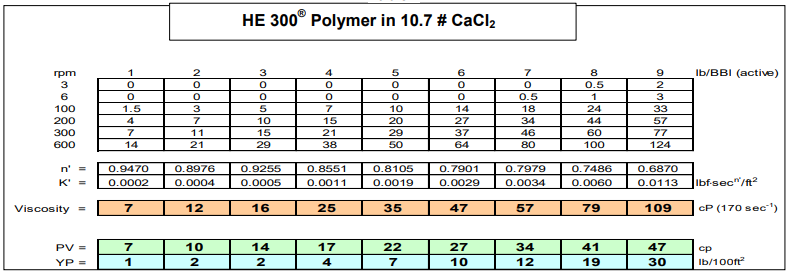

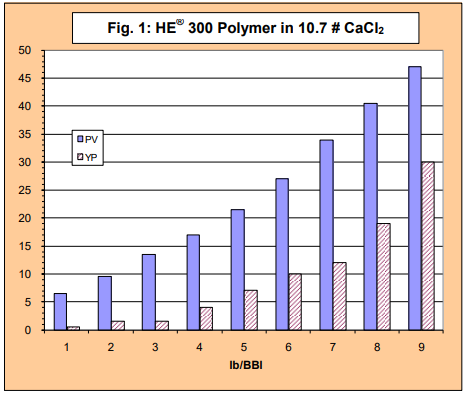

HE® 300 Polymer has been utilized as a thickener for various brines in drilling and completions applications. The HE® 300 Polymer powder is readily dissolved in most brines, yielding rheological properties which describes the polymers performance in a 10.7 lb/gal calcium chloride brine at 70 °F.

- Stability Information

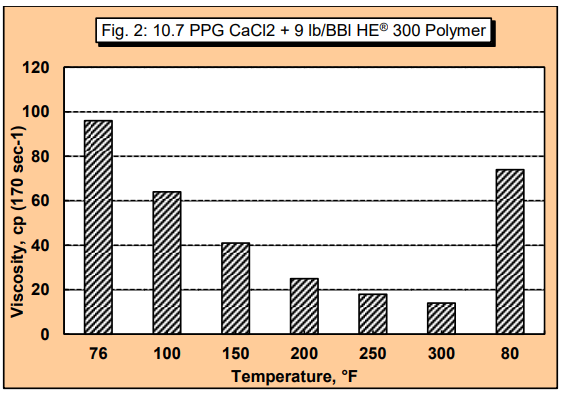

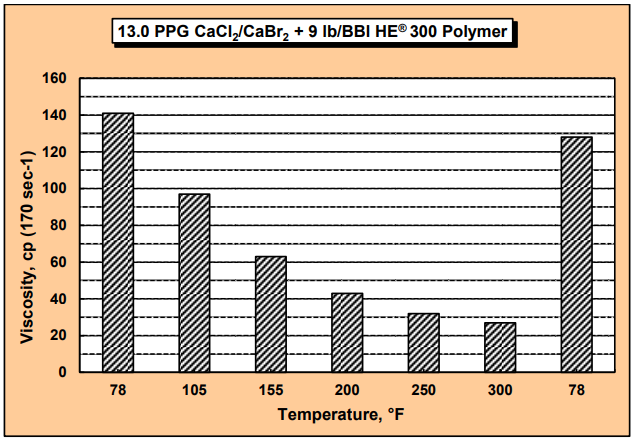

The composition of HE® 300 Polymer provides protection against thermal hydrolysis, which allows the polymer to maintain its solubility in high temperature use and to resist precipitation in the presence of multivalent cations. In this Fan 50 test, the thickened calcium chloride brine was heated incrementally to 300 °F. The fluid was kept at each temperature for one hour before proceeding to the next stage. There was very little change in viscosity during that one-hour period, which demonstrates the polymer stability at high temperatures. Almost all the original viscosity was regained upon cool-down, again indicating no polymer degradation, hydrolysis or loss due to precipitation. In most high temperature applications, the polymer may benefit from the use of oxygen scavengers (e.g. sodium sulfite 0.5 to 4.0 lb/bbl) and a buffer like the sodium bicarbonate/carbonate system. For calcium systems calcium hydroxide is preferred.

Packaging & Availability

- Regional Availability

- Packaging Information

50lb sacks 40 sacks to the pallet.