Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Supplied By

- Industrial Additives Functions

- CAS No.

- 105-59-9

- EC No.

- 203-312-7

- Technologies

- Product Families

Features & Benefits

- Industrial Additives Features

- Product Highlights

JEFFTREAT® AO-832 offers several key advantages:

- Reduces damage to gas treating amines due to oxygen ingress or excessive heat

- Decreases formation of heat stable salts and amine degradation byproducts

- Maintains amine strength through reduced solvent degradation

- Lower corrosion rate due to reduction in heat stable salts

- Key Features

JEFFTREAT® AO-832 offers several key advantages:

- Reduces damage to gas treating amines due to oxygen ingress or excessive heat

- Decreases formation of heat stable salts and amine degradation byproducts

- Maintains amine strength through reduced solvent degradation

- Lower corrosion rate due to reduction in heat stable salts

Applications & Uses

- Markets

- Applications

- Segments

- Applications

- Applicable Processes

- Industrial Additives End Use

- Recommended Applications

- JEFFTREAT® AO-832 is a patent pending blend of ethyleneamines, formulated to reduce oxidation degradation in all gas treating amine products.

- Dosage rate for JEFFTREAT® AO-832 is dependant on oxygen ingress rate to the amine system and other operating parameters of the plant.

- Initial treatment of JEFFTREAT® AO-832 is required for all systems and is dependent on inlet gas oxygen content, total system volume and operating conditions of the amine unit.

- Huntsman technical support personnel will determine required initial treatment of JEFFTREAT® AO-832 as well as maintenance dosage rates.

- Injection of JEFFTREAT® AO-832 should be done on a continuous basis using a metering pump designed for chemical injection.

- Residual levels of JEFFTREAT® AO-832 are monitored by laboratory analysis at Huntsman Advanced Technology Center and recommended dosage rate is optimized based on analysis results.

- JEFFTREAT® AO-832 has proven to be successful in reducing total amine degradation in operating amine systems.

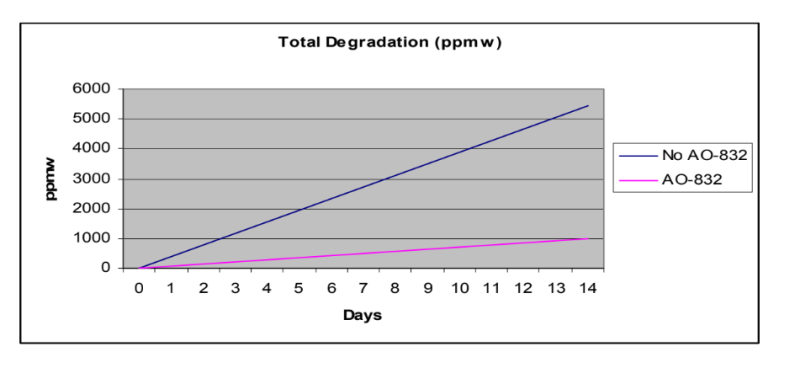

- The graph below illustrates reduction in total degradation products in 2 parallel amine trains with the same inlet gas composition using a 50 weight percent MDEA solution over a 14 day test.

- One unit was operated with JEFFTREAT® AO- 832 and the other was not. Over 14 days, total degradation in the untreated unit was over 5 times more than the unit with JEFFTREAT® AO-832.

-

JEFFTREAT® AO-832 is a patent pending blend of ethyleneamines, formulated to reduce oxidation degradation in all gas treating amine products. Dosage rate for JEFFTREAT® AO-832 is dependant on oxygen ingress rate to the amine system and other operating parameters of the plant. Initial treatment of JEFFTREAT® AO-832 is required for all systems and is dependent on inlet gas oxygen content, total system volume and operating conditions of the amine unit. Huntsman technical support personnel will determine required initial treatment of JEFFTREAT® AO-832 as well as maintenance dosage rates. Injection of JEFFTREAT® AO-832 should be done on a continuous basis using a metering pump designed for chemical injection. Residual levels of JEFFTREAT® AO-832 are monitored by laboratory analysis at Huntsman Advanced Technology Center and recommended dosage rate is optimized based on analysis results.

-

JEFFTREAT® AO-832 has proven to be successful in reducing total amine degradation in operating amine systems. The graph below illustrates reduction in total degradation products in 2 parallel amine trains with the same inlet gas composition using a 50 weight percent MDEA solution over a 14 day test. One unit was operated with JEFFTREAT® AO- 832 and the other was not. Over 14 days, total degradation in the untreated unit was over 5 times more than the unit with JEFFTREAT® AO-832.

- Product Application

- JEFFTREAT® AO-832 additive is an innovative gas treating additive that hinders the oxidative attack of amines and greatly reduces amine degradation.

- Performs by interfering with the oxygen radical in the degradation process.

- Not designed as an oxygen scavenger.

- Shown to successfully reduce bicine formation from MDEA and formulated MDEA solvents n Minimizes heat stable salt formation in gas treating amines.

Properties

- Physical Form

Regulatory & Compliance

- Chemical Inventories

Packaging & Availability

Storage & Handling

- Storage and Handling Information

JEFFTREAT® AO-832 may be satisfactorily stored in carbon steel tanks using steel pipes and pumps. For longer term color stability, it is recommended that the product be stored under an inert atmosphere in type 304 or 316 stainless steel tanks. Low pressure steam coils in storage tanks and steam tracing of transfer lines should be provided in cases where low environmental temperatures may make pumping of the product difficult. Minimum temperature for pumping and injection of JEFFTREAT® AO- 832 is 5 degrees C (41 Degrees F).