Enhanced TDS

Identification & Functionality

- Chemical Family

- Supplied By

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Product Highlights

LOCTITE LIOFOL LA 2790-22 adhesive with LOCTITE LIOFOL LA 5026-21 curing agent is a commercial, twocomponent, solventbased, polyurethane adhesive for flexible packaging laminating. The cured adhesive is optically clear, odor free and elastic.

Applications & Uses

- Markets

- Applications

- Segments

- Applications

- Application Method

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Adhesive & Sealant End Applications

- Product Applications

Designed for use in high performance, film/film and film/foil food packaging laminations. It has excellent heat and chemical resistance. Its primary use is for laminations exposed to pasteurization, boiling water, and sterilization and retort conditions. Due to the wide variability of film additives, materials, surface conditions, process conditions, and performance criteria, pretesting on your substrates and production equipment is required to determine if this adhesive system will meet all your needs. This adhesive also can be used for general-purpose food packaging laminations, health care, pharmaceutical and cosmetic applications.

- Processing Information

Application Method

The recommended method of application for this adhesive mix is with a standard gravure roll coater. When using this type of conventional coating equipment, apply the adhesive at 20-35% TSC for best results. Depending upon the film or foil combinations, and the end use of the lamination, apply approximately 2.5 – 3.0 lbs/ream (4.0-4.9 gm/m2 ) coating weight of adhesive. Deep draw applications often require higher coating weights to accommodate the package elongation.

Drying:

Optimum drying conditions are dependent on the specific machine speed, coating weight, dwell time, and efficiency of the dryer. A system with good air volume and exhaust is more effective than extremely high temperature to remove the solvents. The drying conditions should correlate to machine speed. Dryers with multiple zones should be staged from a lower temperature in the first zone to higher temperatures in successive zones. This will facilitate solvent removal without adhesive skinning. Extremely high temperatures and over-drying the adhesive can result in cure irregularities and lower performance. Caution should be taken to establish the optimum process conditions for your equipment.

Combining Nip:

The lamination of the primary and secondary substrates should exhibit excellent initial tack when combined at heated nip temperatures of 149-176°F (65-80°C). Pressure and temperature of the laminating nip may require adjustment based on the appearance, degree of wrap angle, dwell time, and thickness of the substrates.

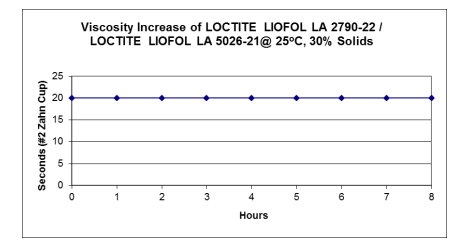

Pot Life:

Typically, this product at 30% solids in a closed container has a working time of 8 – 12 hours without substantial viscosity increase. However, solvent moisture content, relative humidity, temperature, solvent loss, and % running solids can all shorten the pot life of the adhesive mixture. Due to the chemical activity of the material, using material that is older than 8-12 hours is not recommended

Curing:

The laminate can be further processed, rewound and slit after 3-4 days of curing at room temperature. To achieve complete curing, i.e., total resistance to severe environments, allow 7-10 days of storage at room temperature. Cure rate may depend on film combination.

Equipment Clean Up:

Clean up of the application station is accomplished with solvents such as ethyl acetate, methyl ethyl ketone, acetone, or toluene. Protective gloves should be worn.

Properties

- Color (Properties)

- Appearance

- Clear to transparent yellow

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

Storage & Handling

- Storage Information and Shelf Life

The LA 2790-22 adhesive has a storage life of twelve months from date of manufacture. The LA 5026-21 coreactant has a storage life of six months from date of manufacture. They should be held at normal warehousing temperatures and stored in the original, unopened containers. Containers of the adhesive or curing agent should not remain open for an extended period of time. Material from opened containers should be consumed within a short period. It is necessary to use all the adhesive, once the container is opened, unless there is means of purging the container with dry nitrogen.

- Handling Information

The coreactant, as received, has chemically active Isocyanate groups that will react with water, alcohols, amines, and similar materials containing active hydrogen groups. Reseal containers and keep them tightly closed to maximize the storage life. Nitrogen purging of original containers will have a similar effect. Upon request, a DRIERITE® desiccant unit will be supplied with the first drum to ensure that dry air enters the drum as adhesive is withdrawn.