Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Supplied By

- Base Chemicals Functions

- CAS No.

- 68909-77-3

- EC No.

- 272-712-1

- Technologies

- Product Families

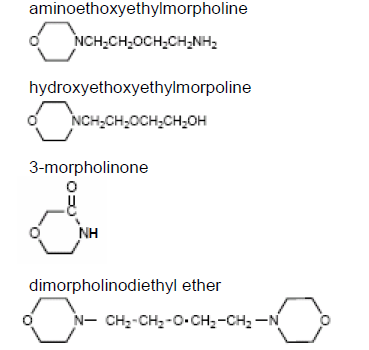

- Chemical Constituents

Applications & Uses

- Markets

- Applications

- Segments

- Base Chemicals End Uses

Properties

- Physical Form

- Appearance

- Clear, dark amber liquid

- Odor

- Ammonia like

- Miscible in

- Water

Safety & Health

- Toxicity and Safety Information

- The acute oral LD50 of Amine C-8 is approximately 8.75 g/kg and the product is considered, therefore, to be practically nontoxic by swallowing in single doses.

- The undiluted product appears to penetrate skin readily, since the LD50, by single 24-hour skin contact to rabbits is about 3.85 g/kg.

- Nevertheless, the latter figure indicates only a moderate to slight degree of hazard insofar as actual absorption through the skin is concerned.

- Skin irritation to rabbits is slight at the lowest dosage and increases in severity with increasingly higher dosages.

- Undiluted Amine C-8 is very irritating to eyes.

- As with other caustic materials, dilution with water would be expected to reduce this hazard.

- In case of eye contact, the eye should be irrigated continuously with water for at least 15 minutes.

- A physician should see all cases in which undiluted Amine C-8 has splashed into the eye.

- All spills of Amine C-8 on the skin should be washed off promptly with soap and water.

- If clothing has become saturated, it should be removed at once, and affected skin areas washed thoroughly with soap and water.

- Such measures will aid in preventing immediate irritant effects as well as the development of skin sensitivity that may occur in susceptible persons from prolonged contact or repeated exposure.

- Vapor concentrations of Amine C-8 that are likely to develop under ordinary working conditions would constitute little immediate hazard to health.

- Acutely dangerous exposures might be expected to occur only after massive spills in closely confined areas. Although no threshold limit for Amine C-8 vapor has been established, the breathing of high concentrations should be avoided.

- A chemical cartridge respirator or gas mask, offering protection against organic vapor, should be worn when entering vessels for purposes of cleaning or maintenance unless thoroughly flushed with water beforehand.

- It has been observed that certain individuals exposed to vapor of aliphatic amines may complain of hazy vision as from a film over the eye.

- This symptom may develop at vapor concentrations that cause no obvious discomfort.

- It is said to result from a mild degree of corneal edema, and disappears without residual injury several hours after discontinuance of exposure.

- This is reported to occur after exposure to a number of amines and must be regarded as a sign of overexposure.

- Amine C-8 should be handled only in well-ventilated areas.

- Wherever practical, process equipment should be provided with exhaust ventilation to prevent buildup of vapor concentrations in the workroom atmosphere.

- Personal protective equipment that should be used by persons handling concentrated solutions of Amine C-8 is:

- Rubber gloves

- Rubber footwear

- Chemical goggles

- Protective overalls

- Maintenance personnel at work on equipment that has contained Amine C-8 should wear the above listed protective equipment.

Packaging & Availability

Storage & Handling

- Storage and Handling Information

- Carbon steel is a satisfactory material for storing and handling Amine C-8.

- Copper, zinc, lead, or alloys containing any of these materials should not be used since they will be attacked by the product.

- The freezing point will vary over a wide range.

- Since it can freeze as high as 50°C (122°F), it will be necessary to provide heat to the storage tank.

- Generally, this can be done by utilizing either internal or external heating coils of a suitable area to heat the tank contents.

- If these coils are internal, they should be built into the tank about six inches above the floor and operated on low-pressure steam.

- The coils should be constructed in such a manner as to allow the condensate to drain.

- Mild steel is acceptable for transfer lines. Since the product will leach conventional pipe dopes from threaded connections, the lines should be welded or flanged.

- Satisfactory gasketing materials are Garlock 7021, U.S. Rubber 899, John Crane 333, Johns- Manville 70, or equivalent.

- Carbon steel centrifugal pumps are satisfactory.

- Either pump packing or a mechanical seal may be used.

- Braided Teflon or asbestos are satisfactory packing materials.

- Seals may be John Crane Type 9, Durametallic Type RO-TT, or equivalent with either stellite and carbon or tungsten faces and Teflon V-rings.