Enhanced TDS

Identification & Functionality

- Carrier

- Chemical Family

- Chemical Name

- Supplied By

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

Applications & Uses

- Markets

- Applications

- Segments

- Applications

- Application Method

- Compatible Substrates & Surfaces

- Adhesive & Sealant End Applications

- Application and Usage Information

Target Application

Designed for adhesion to high slip films used in film/film and food-packaging laminations. This product has excellent heat and chemical resistance. Due to the wide variability of film additives, materials, surface conditions, process conditions, and performance criteria, pre-testing on your substrates and production equipment is required to determine if this adhesive system will meet all your needs.

Other Applications

This adhesive also can be used for general-purpose food packaging laminations, health care, pharmaceutical and cosmetic applications.

Adhesive Mixing Instructions

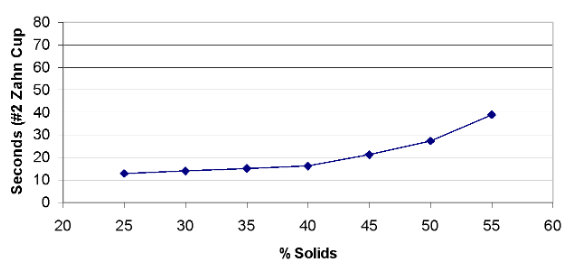

% Running Solids: Determine the adhesive viscosity based on your application method, cylinder selection and desired coating weight. Typically, a coating weight between 1.5 – 2.0 lb/ream (2.4 – 3.3 gm/m2) is used for standard laminations. The chart below may be used for reference and is typical for Tycel 7966/7287 when diluted with Ethyl Acetate. Determine the % running solids required:% Solids vs. Viscosity for 7966 / 7287

Solvent Selection: Select a dilution solvent. Urethane grade ethyl acetate is recommended. However, methyl ethyl ketone, or acetone may also be used. Using a solvent other than ethyl acetate will change the viscosity curve shown above.Water content of the selected solvent should not exceed 300 ppm. High water content of the solvent can cause an undesirable reaction with the isocyanate that can alter the final performance of the adhesive mixture.

Dilution: Calculate the amount of solvent required to dilute the adhesive and curing agent to the desired % running solids. The chart that follows may be used to determine the amount of solvent required for each of the components to achieve the desired % solids.

Use the following solvent amount to adjust the total solids by weight. (pounds of solvent needed per pound of adhesive or coreatant)

Percent Solids as Supplied 100 80 75 70 65 60 55 50 45 40 35 30 25 20 % Solids Desired 70 0.43 0.14 0.07 65 0.54 0.23 0.15 0.08 60 0.67 0.33 0.25 0.17 0.08 55 0.82 0.45 0.36 0.27 0.18 0.09 50 1 0.6 0.5 0.4 0.3 0.2 0.1 45 1.22 0.78 0.67 0.56 0.44 0.33 0.22 0.11 40 1.5 1 0.87 0.75 0.62 0.5 0.37 0.25 0.12 35 1,86 1.29 1.14 1 0.86 0.71 0.57 0.43 0.29 0.14 30 2.33 1,67 1.5 1.33 1.17 1 0.83 0.67 0.5 0.33 0.17 25 3 2.2 2 1.8 1.6 1.4 1.2 1 0.8 0.6 0.4 0.2 20 4 3 2.75 2.5 2.25 2 1.75 1.5 1.25 1 0.75 0.5 0.25 15 5,67 4.33 4 3.67 3.33 3 2.67 2.33 2 1,67 1.33 1 0.67 0.33 10 9 7 6.5 6 5.5 5 4.5 4 3.5 3 2.5 2 1.5 1 Adhesive Mixing: Weigh the desired amount of adhesive into a clean, dry, container. While stirring under slow agitation, add the total amount of solvent calculated based on the desired batch size. Stir slowly for approximately 10 minutes. Slowly add the curing agent to the stirring adhesive mixture. Stir for an additional 10 –15 minutes. Cover the container to prevent additional solvent loss.

Processing Information

Application Method : The recommended method of application for this adhesive mix is with a standard gravure roll coater. When using this type of conventional coating equipment, apply the adhesive at 30 – 45% TSC for best results. Depending upon the film or foil combination, and the end use of the lamination, apply approximately 1.5 – 2.0 pounds / ream (2.4 – 3.3 gm/m2) coating weight of adhesive. Deep draw applications often require higher coating weights to accommodate the package elongation.Drying: Optimum drying conditions are dependent on the specific machine speed, coating weight, dwell time, and efficiency of the dryer. A system with good air volume and exhaust is more effective than extremely high temperature to remove the solvents.

The drying conditions should correlate to machine speed: Example: 57 – 71oC (135-160oF) at 165 fpm 71 – 93oC (160-200oF) at 500 fpm

Dryers with multiple zones should be staged from a lower temperature in the first zone to higher temperatures in successive zones. This will facilitate solvent removal without adhesive skinning.

Extremely high temperatures and over-drying the adhesive can result in cure irregularities and lower performance. Caution should be taken to establish the optimum process conditions for your equipment.

Combining Nip: The lamination of the primary and secondary substrates should exhibit excellent initial tack when combined at heated nip temperatures of 122 – 158°F. Pressure and temperature of the laminating nip may require adjustment based on the appearance, degree of wrap angle, dwell time, and thickness of the substrates.

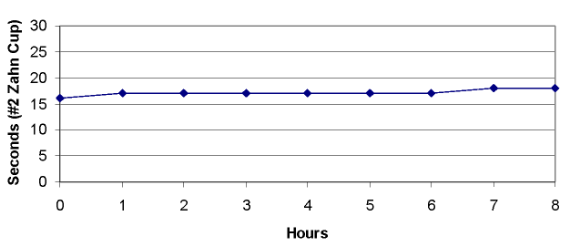

Pot Life: Typically, this product at 40% solids in a closed container has a working time of 8 – 12 hours without substantial viscosity increase. However, solvent moisture content, relative humidity, temperature, solvent loss, and % running solids can all shorten the pot life of the adhesive mixture. Due to the chemical activity of the material, using material that is older than 8 –12 hours is not recommended.Viscosity Increase of 7966 / 7287 @ 25°C, 40% Solids

Curing: The laminate can be further processed, rewound and slit after 1-2 days of curing at room temperature. To achieve complete curing, i.e., total resistance to severe environments, allow 7 – 14 days of storage at room temperature. Cure rate may depend on film combination.

Equipment Clean Up: Clean up of the application station is accomplished with solvents such as ethyl acetate, methyl ethyl ketone, acetone, or toluene. Protective gloves should be worn.

Properties

- Physical Form

- Appearance

- Clear, slightly yellow

Regulatory & Compliance

- Certifications & Compliance

Packaging & Availability

Storage & Handling

- Shelf Life

- 12 months

- Storage and Shelf Life Information

Storage and Shelf Life:

These products have a storage life of twelve months from date of manufacture. They should be held at normal warehousing temperatures and stored in the original, unopened containers. Containers of the adhesive or curing agent should not remain open for an extended period of time. Material from opened containers should be consumed within a short period. It is necessary to use all the adhesive, once the container is opened, unless there is means of purging the container with dry nitrogen.

Handling Information:

The adhesive, as received, has chemically active Isocyanate groups that will react with water, alcohols, amines, and similar materials containing active hydrogen groups. Reseal containers and keep them tightly closed to maximize the storage life. Nitrogen purging of original containers will have a similar effect. Upon request, a DRIERITE® desiccant unit will be supplied with the first drum to insure that dry air enters the drum as adhesive is withdrawn.

Positive fresh air ventilation is necessary: otherwise use air supplied hood or chemical facemask. Avoid prolonged breathing of vapors and mists. In case of persistent coughing, call a physician.

Keep adhesive away from heat, sparks and open flame. Avoid prolonged contact with skin. Wash hands thoroughly after using or before smoking or eating.